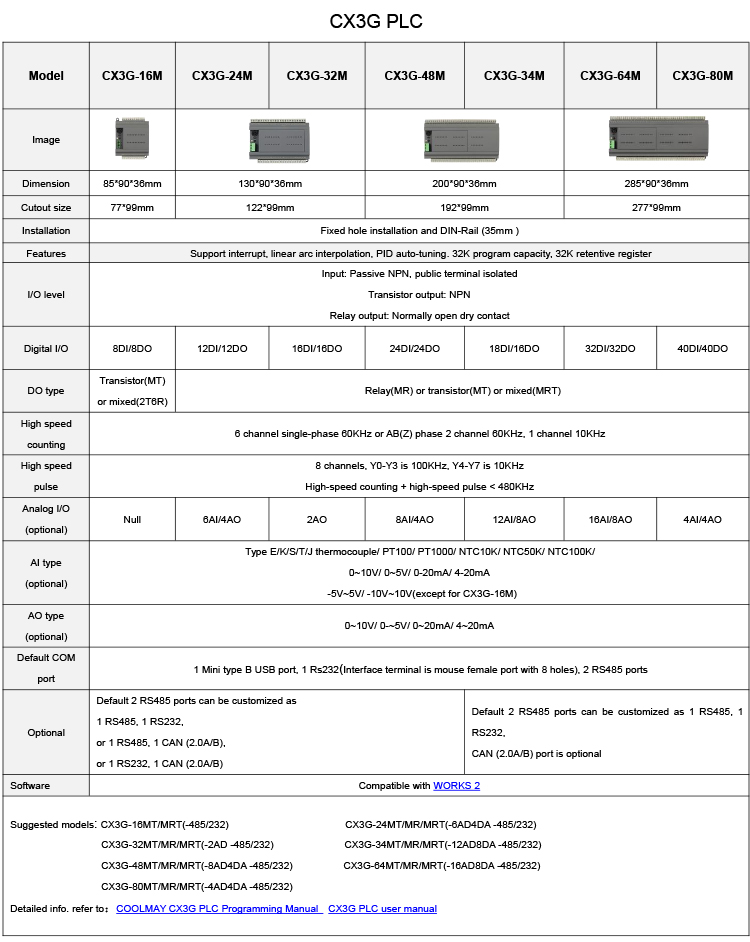

CX3G-24MT/MR/MRT (-6AD4DA-485/232)

Features: The power supply is external, safe and efficient, the space occupancy is greatly reduced, and the failure rate is reduced by 90%.

Note: MT is the transistor output (maximum load: 500mA); MR is the relay output (maximum load: 5A); MRT is the relay transistor mixed output.

The switch is a selectable transistor or relay.

1.If the switch quantity is selected to be 12 in and 12 out, then the analog quantity is up to 6 in 4 out.

*CX3G-24M supports 12DI/12DO,6AD/4DA

*Default as 2 RS485 ports ,and can be customized as 1RS485,1 RS232,

or 1 RS485,1CAN(2.0A/B),

or 1 Rs232,1 CAN(2.0A/B)

*High speed pulse Y0-Y3 100KHz,Y4-Y7 10KHz

*High speed count+high speed pulse≤480KHz

Features:

1. Compatible with Mitsubishi Software WORKS 2;

2. It can be specially encrypted. If the password is set to 12345678, illegal reading is completely prohibited.

3. The switch quantity and analog quantity are highly integrated and can be flexibly selected;

4. Rail mounting and fixing hole installation are two installation methods, which is convenient to install;

5. The appearance is flat, 36mm thickness, occupying a small space;

6. Powerful, basically can meet all the requirements of small and medium-sized equipment;

7. Opening size: 122*99mm;

8. Dimensions: 130*90*36mm.

◆ Product Parameters

▶▶▶ Our products are tested before shipment and are packed with Standard export cartons.

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved