Related Products

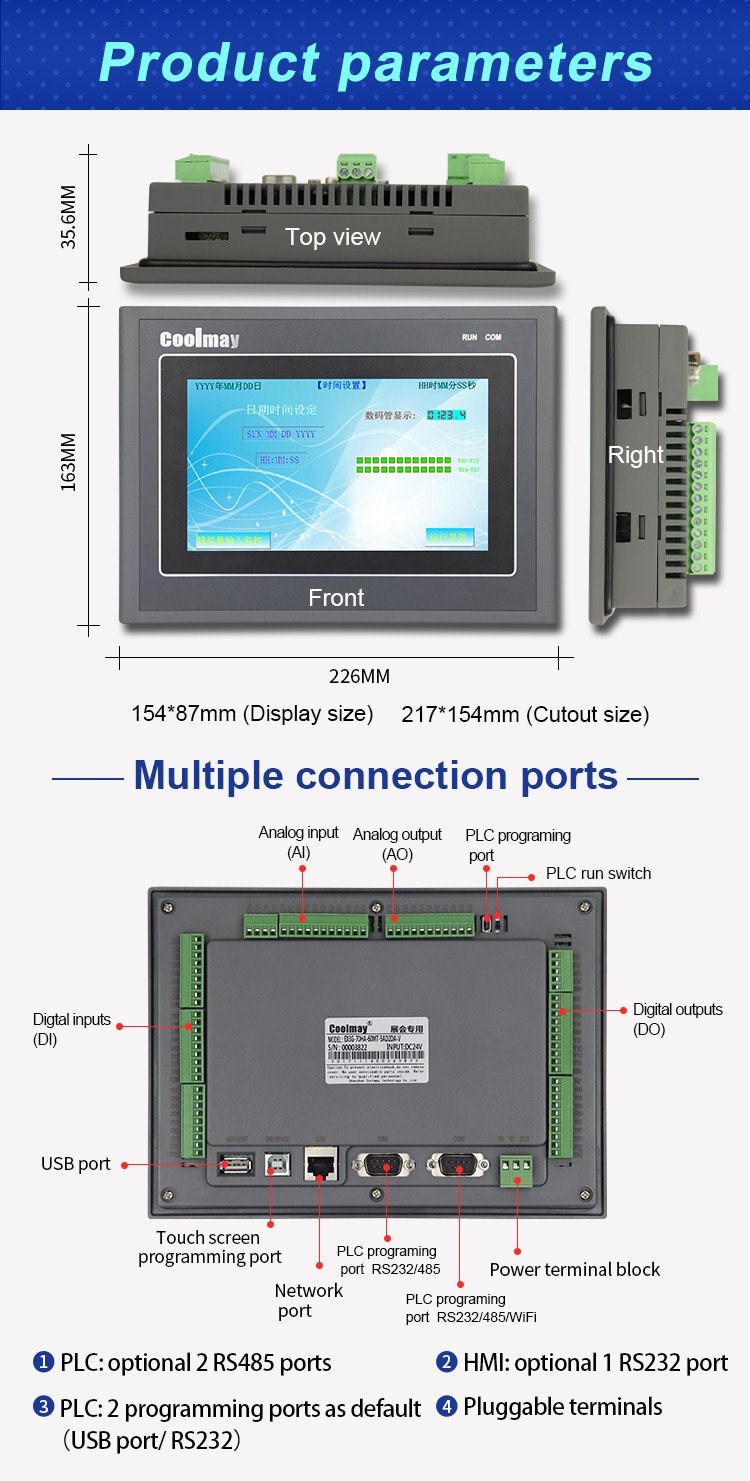

* 7 inch HMI+PLC

* 800*480 pixels resolution

* Default HMI download port, USB 2.0

* Optional RS232 or RS485 on HMI

* Max 30DI/30DO

* Support high speed functions

* Max 16AI/8AO, multiple analog types

* Default RS232 port on PLC and optional RS485 ports

* Optional CAN, Ethernet port, WIFI

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved