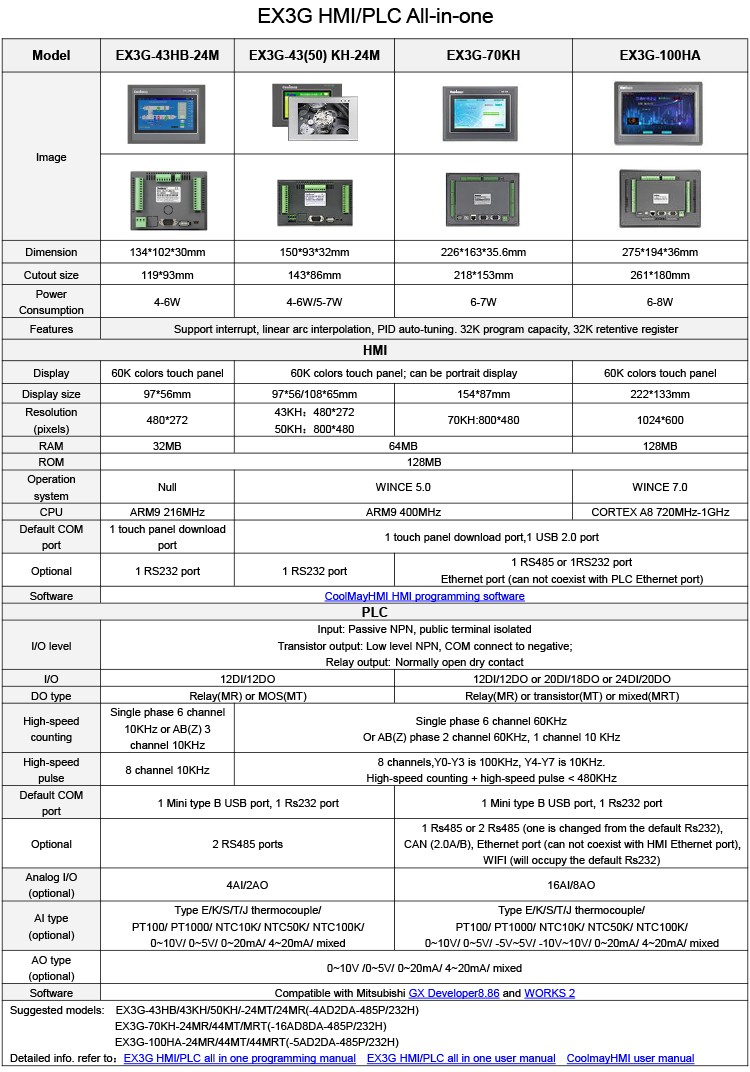

EX3G-50KH-24M(-4AD2DA-485P/232H)

The maximum amount of switching is 12 in 12 out (switching transistor or relay can be selected); the analog quantity is up to 4 in 2 out;

Features: The power supply is external, safe and efficient, the occupied space is greatly reduced, and the failure rate is reduced by 90%. The input and output and power terminals are all pluggable and easy to install and maintain.

Coolmay EX3G-50KH Series 5-inch PLC HMI All In One integrates PLC controller, HMI, input/output and analog control. It is powerful, highly integrated, and has the advantage of saving installation space and reducing cost. It can be flexibly customized according to customer requirements. It is an upgraded product of traditional touch screen and PLC, and comes with WINCE system, completely replacing the industrial computer, which is more powerful than the industrial computer.

In particular, our PLC HMI All In One input and output terminals and power terminals use pluggable terminals, making installation and maintenance particularly convenient. Even if the equipment fails, the equipment manufacturer only needs to replace one without the need for on-site service. Reduce your product maintenance costs.

Product parameters:

Display: 65536 true color 5" TFT LCD screen, 800 * 480 pixel resolution

Brightness: 300cd / m2

Power consumption: 5-7W

Running memory: RAM:64MB. ROM:128MB. support WINCE 5.0 system;

CPU: ARM9 core 400MHZ.

Dimensions: 150*93*32mm;

Display size: 108*65mm;

Opening size: 143*86mm.

1.communication port: 2 Rs485 COM ports.

2.The single 6 channel 60KHz,or 2 AB 60KHz+1AB 10KHz,or 2 ABZ 60KHz+1AB phase 10KHz.

The high speed pulse is 8 channels,Y0-Y3 is 100KHz,Y4-Y7 is 10KHz.High-speed counting+high-speed pulse<480KHz.

Coolmay EX3G-50KH 5-inch PLC HMI All In One features:

1. Compatible with Mitsubishi Software WORKS 2;

2. It can be specifically encrypted. If the password is set to 12345678, illegal reading is completely disabled.

3. The switch quantity and analog quantity are highly integrated and can be flexibly selected;

4. The rail mounting and fixing holes are installed in two ways, which is convenient to install;

5. The appearance is flat, the thickness is 36mm, and the occupied space is small;

6. Powerful, basically meet all the requirements of small and medium-sized equipment.

▶▶▶ Our products are tested before shipment and are packed with Standard export cartons.

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved